Our Services

At Global Plastic Recycling, we proudly bring over five years of extensive expertise in grinding, toll grinding, and comprehensive scrap recovery services that are tailored to effectively meet the diverse needs and specific requirements of our valued clients. Our state-of-the-art facilities, combined with our highly skilled team, ensure precision and accuracy in every project we undertake, delivering high-quality results that significantly drive both sustainability and efficiency. By partnering with us, clients can benefit from exceptional customer service, reliable adherence to project deadlines, and a steadfast commitment to excellence that positions us as the go-to grinding company they can confidently trust. Our unwavering dedication to fostering strong and lasting relationships with our customers truly sets us apart in the industry, ensuring that their unique requirements are always met with the utmost professionalism and genuine care.

We support you with dedicated service in Plastic Grinding

Partnering with Global Plastic Recycling as your dedicated grinding partner provides numerous benefits that streamline your operations and reduce overhead costs. By eliminating in-house processing, you free up valuable resources and personnel, allowing your team to focus on core activities that drive growth. Additionally, you can say goodbye to expenses related to equipment storage and maintenance, as we handle all aspects of the grinding process efficiently and effectively. This partnership not only enhances operational efficiency but also ensures that you receive high-quality recycled materials, helping you meet sustainability goals while optimizing your supply chain.

Grinding

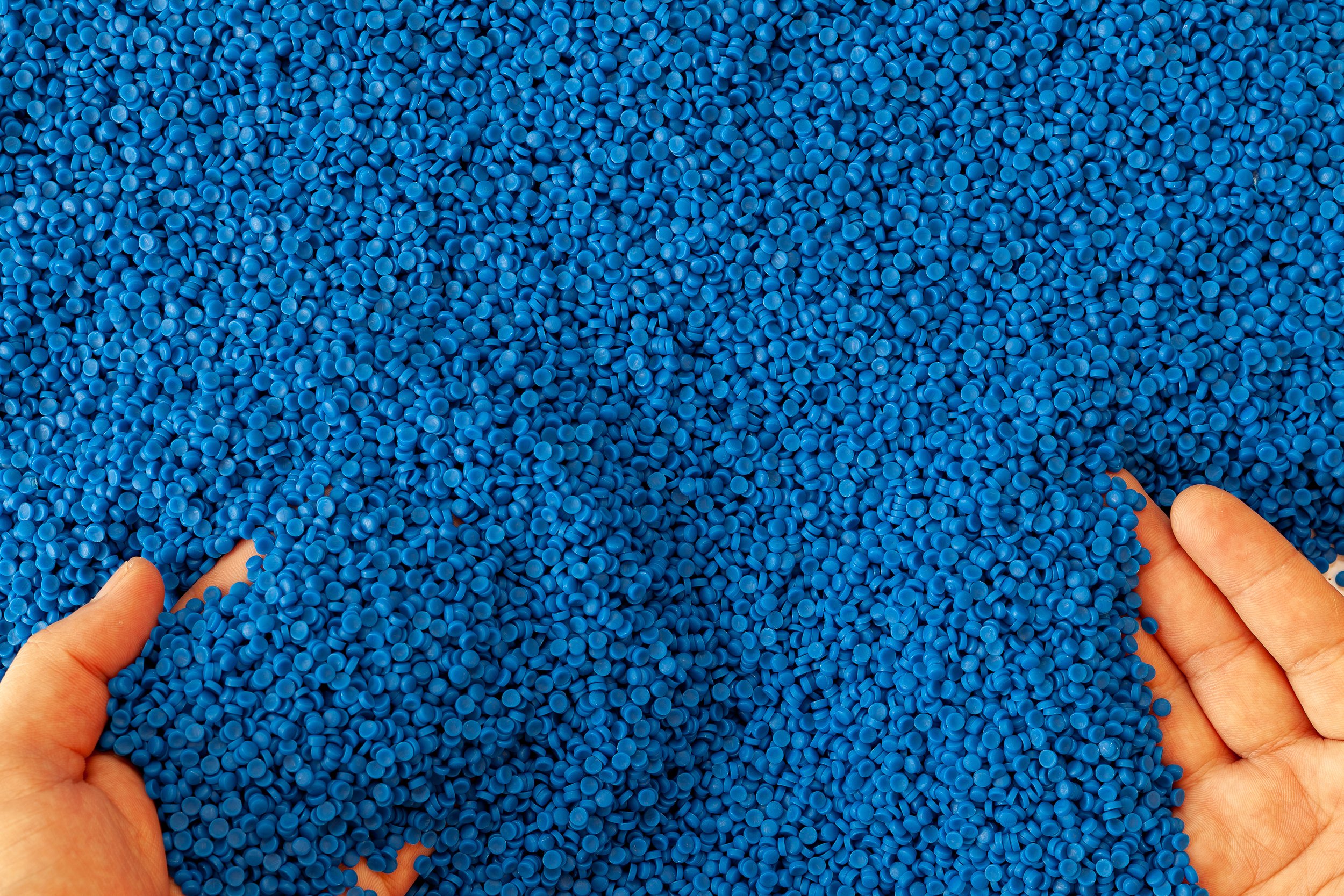

Plastic grinding is a crucial step in the recycling process, where used plastic materials are mechanically reduced to smaller sizes, facilitating efficient processing and reuse. At Global Plastic Recycling, we have honed our expertise over five years, ensuring that our grinding methods optimize the quality of the recycled material while minimizing waste. This meticulous process not only enhances the recyclability of plastics but also contributes significantly to environmental sustainability. Our commitment to eco-friendly practices drives us to continuously improve our techniques, aligning our operations with the broader goal of reducing plastic pollution and promoting a circular economy.

Toll Grinding

Plastic toll grinding is a vital process in the recycling industry aimed at transforming waste plastic into reusable material. In this procedure, post-consumer or post-industrial plastic is collected, sorted, and fed into specialized grinding machines that convert the plastic into small, uniform particles or flakes.

Our expertise in toll grinding ensures that these ground materials can be reprocessed and molded into new products, effectively reducing the reliance on virgin plastic and minimizing environmental impact. The purpose of toll grinding extends beyond just recycling; it plays a crucial role in supporting manufacturers by providing a steady stream of recycled feedstock. This contributes to a circular economy that conserves resources and reduces landfill waste, aligning with our commitment to sustainable practices in the plastic recycling industry.

Scrap Recovery

Scrap recovery is a critical process that involves the collection, sorting, and recycling of waste materials to reclaim valuable resources and reduce environmental impact. This process not only minimizes landfill waste but also conserves energy and reduces the need for virgin materials, thereby decreasing the carbon footprint associated with manufacturing. At Global Plastic Recycling, we are committed to implementing efficient scrap recovery methods that reflect our expertise in sustainable practices. Our dedication to environmental stewardship drives us to continuously improve our processes, ensuring that we contribute positively to the ecosystem while supporting a circular economy.

GRADES WE PURCHASE

-

ABS

PETG

PET

Polycarbonate (PC)

PC/ABS

-

PP- Polypropylene

Copolymer

Homopolymer

-

PE- Polyethylene

HDPE

HMW

-

NYLON (Filled and Unfilled )

6

6/

-

PVC

Rigid